Quarter Sawn lumber possess advantages over plain sawn lumber because of the orientation of the growth rings. Because the growth rings in quarter-sawn wood run uniformly parallel along the entire board the wood does not shrink and expand with seasonal variation in moisture as much as flat sawn wood. In addition because of the orientation of the growth rings, quarter-sawn wood is less prone to shrinkage, twisting, cupping and in many cases rot because sap wood is easier to isolate in manufacturing process. Purchasing quarter-sawn wood often requires direct contact and contract with the sawyer.

In acoustic guitars, quarter sawn wood is often used, especially for the sides which must be steam bent to produce compound curves.

Plain Sawn:

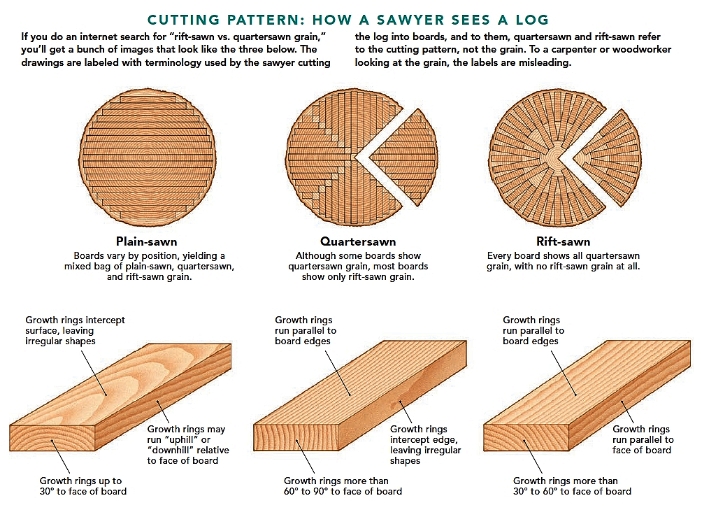

The most common method of sawing and consequently most lumber is plain sawn. Plain sawn lumber is obtained by making the first saw cut on a tangent to the circumference of the log and the remaining cuts parallel to the first. This method provides the widest boards and least waste; therefore, it is the most economical.

Plain Sawn (tangential grain) is easily recognized by it cathedral (Gothic arch) effect on the face of the board. The end grain will have semi-circles and plain sawn lumber tends to cup more than quartered or rift sawn lumber.

What is the ecological benefit to quarter sawing?

There is a significant ecological benefit derived by using quartered and rift lumber compared to plain-sawn lumber. A quarter-sawn log is "sawn from the inside out," resulting in more usable wood from each log. Additionally, the quarter-sawing process uses less energy. Finally, a greater percentage of high-grade lumber is produced from each quarter-sawn log, allowing use of lower-grade logs.

Quarter Sawn Oak

How can quarter-sawn lumber benefit my product?

Our carefully machined lumber provides you with the structural integrity and unique grain patterns you want. Stability and appearance pass from boards to your finished products.

If quarter sawing is so good, why don't all sawmills do it?

For most, the art of quarter sawing has been lost over the years. Like many superior practices of the past, quarter sawing lost favor to plain sawing techniques. Plain sawing is easier, cheaper, and quicker... but it results in more waste, less grain characteristic and less stable lumber.

Is there a difference in cost between quartered lumber and plain-sawn lumber?

Quarter sawing is a specialized technique requiring more time and greater skill to produce. Logically, lumber prices are slightly higher than plain sawn.

What are the structural qualities of quarter-sawn lumber?

Quarter-sawn lumber is the uncontested winner when compared to plain- (or flat-) sawn lumber. Quarter-sawn features include:

- Reduces shrinking and swelling in lumber width.

- Reduces twisting, warping and cupping.

- Less prone to surface checking.

- Wears more evenly in all applications.

- Does not allow liquids to readily pass through it.

- Holds paint better.

- Smooth surface as raised grain is not pronounced.

references:

(1) AllWoodWork.com

(2) Lumber Post

(3) WoodWeb

(4) This information provided compliments of the Hardwood Manufacturers Association

(5) WPMA - Wood Products Manufacturers Association