|

Veneer wood furniture begins with thin layers of wood glued together with the grain at right angles over a thick core. This crisscross design reduces the chances of splitting or cracking. Plus, the glue is the equally strong, waterproof adhesive used in aircraft and marine construction, so the end result is actually stronger than the natural wood. Many people mistakenly assume that veneered furniture is inferior to or cheaper than solid wood; however, veneers quite often are used in high end furniture pieces and it can be more costly than solid wood.

Veneer Hardwoods

Beautiful:

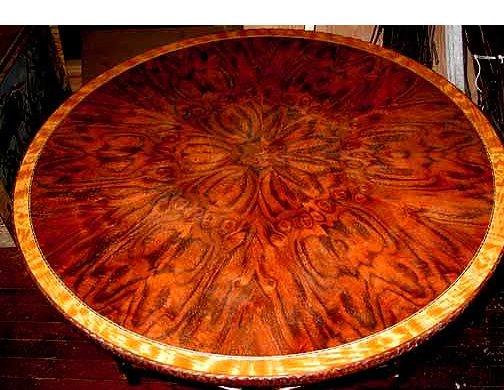

The best, most interesting logs are cut into veneer. This is largely an economic decision--sellers and veneer makers can make more money from a high quality log sliced into veneer than they can from sawing it into boards. And certain cuts, such as burls, are structurally unsound in 'the solid'. These beautiful woods can rarely be utilized unless they're sliced into veneer

Environmentally Kind:

Saw timber is typically sawn into 1" thick boards. The saw cuts a kerf between boards 1/4" thick that winds up as sawdust. Veneer is not cut from the log but sliced with a knife (like lunch meat) into 1/32" leaves or sheets. That produces 32 veneer surfaces for every 1 that is gotten from a board and with no wood wasted as sawdust another 8 sheets where the sawblade would have gone. That's 40 surfaces of wood veneer for every 1 of solid wood.

Creates New Design Possibilities:

Since veneer is so thin and is glued to a stable substrate it allows designs and arrangements of the wood that would fail in solid wood. Solid wood, even kiln-dried, moves or works from summer through winter through summer again. A radiant table top would be impossible in solid lumber because the seams would open in winter and swell tightly shut in summer. Cross grain designs such as aprons and edge bandings are also impossible in solids. Solid burls are also largely unusable but frequently used in veneer.

Stable:

Since veneer is glued with a waterproof adhesive to a stable substrate it produces surfaces not prone to warp or splitting or seasonal movement.

Substrates:

Plywood and medium density fiberboard are substrates used for furniture, are made from low quality trees. This means a market is provided the landowner for these trees. This leads to better forests over time since the trees remaining grow better and faster with less competition for resources. Its like weeding your garden only a lot bigger.

references:

(1) WPMA - Wood Products Manufacturers Association

(2) AWFS - Association of Woodworking & Furnishings Suppliers

(3) Hardwood Manufacturers Association